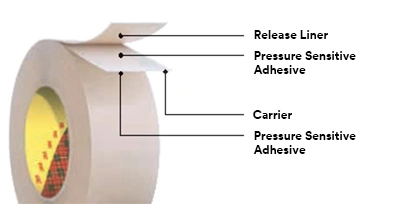

Double coated tapes consist of pressure-sensitive adhesive on both sides of a carrier. The carrier reinforces the substrate while, at the same time, allows for easier dispensing. Because of the added layer, double coated tapes tend to be thicker and will generally have lower temperature resistance simply due to the limitations of the carrier that the adhesive rests on.

When two distinct adhesives are needed in order to join dissimilar surfaces, double coated tapes are the preferred choice and are often referred to as "differential tapes." For instance, you may have a need for a permanent adhesive on one side of a carrier and a removable on the opposite.

Uses of Double Coated Tape

Double coated tapes, also known as double sided tapes, can be used to reinforce substrates. For instance, they can be used to join porous substrates, such as foam, to help keep the substrate from reshaping itself. They are also used to help fill any gaps between parts that an adhesive transfer tape would cover. Double coated tapes are often referred to as "spacers" in this type of application.

- Special Tapes and Adhesives

- Polycarbonate Film (Sabic Lexan) PC Film

- Surface Protection Tapes / Low tack PE Film

- Scapa Tape

- Double Side Tape - (General Purpose)

- Self Adhesive Vinyls Film (Screen Printable)

- 3M™ Adhesive Transfer Tapes

- 3M™ Single Coated Tapes

- 3M™ Double Coated Tapes

- 3M™ Electronics Assembly Solutions

- 3M™ Foam Tapes

- 3M™ Medical Materials and Technologies

- 3M™ Performance Label Materials

- 3M™ VHB™ Tapes

- 3M™ Commercial Solutions

- 3M™ Membrane Switch Spacers

- 3M™ Reclosable Fasteners