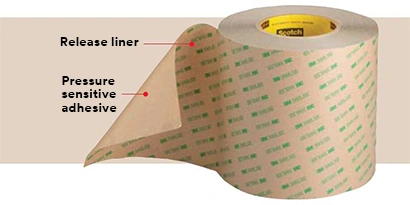

3M™ Adhesive Transfer Tapes can be thought of as glue on a liner. They are used in a wide range of applications ranging from basic graphic attachment to flexible circuitry, and they are used to provide long term bonds to graphic nameplates and overlays in a wide variety of markets, including: Aerospace, Medical, Industrial Equipment, Appliance and Electronics.

Industrial Adhesive Transfer Tape Properties

Industrial adhesive transfer tapes are generally between 1-5 mils and are very conformable making it ideal for high speed processing of parts. Adhesive transfer tapes are also coated onto a removable release liner that protects the adhesive until the liner is removed, and with pressure, these tapes will stick without any other type of activation method. The tapes can be broken down into three distinct application groupings:

- High Surface Energy & Harsh Environments

- Low Surface Energy & Challenging Surfaces

- General Industrial, U.V. Resistant and Cold

Probably the easiest way to distinguish between the need for high and low surface energy adhesives is to use a freshly waxed car as an example. When a car hasn't been waxed in some time, water spreads and runs off the car. This is an example of how a high surface energy substrate would react as well. The molecular attraction causes the water to "flow." A waxed car would exhibit low surface energy since the water would bead up and not "flow" off of the surface.

- Special Tapes and Adhesives

- Polycarbonate Film (Sabic Lexan) PC Film

- Surface Protection Tapes / Low tack PE Film

- Scapa Tape

- Double Side Tape - (General Purpose)

- Self Adhesive Vinyls Film (Screen Printable)

- 3M™ Adhesive Transfer Tapes

- 3M™ Single Coated Tapes

- 3M™ Double Coated Tapes

- 3M™ Electronics Assembly Solutions

- 3M™ Foam Tapes

- 3M™ Medical Materials and Technologies

- 3M™ Performance Label Materials

- 3M™ VHB™ Tapes

- 3M™ Commercial Solutions

- 3M™ Membrane Switch Spacers

- 3M™ Reclosable Fasteners